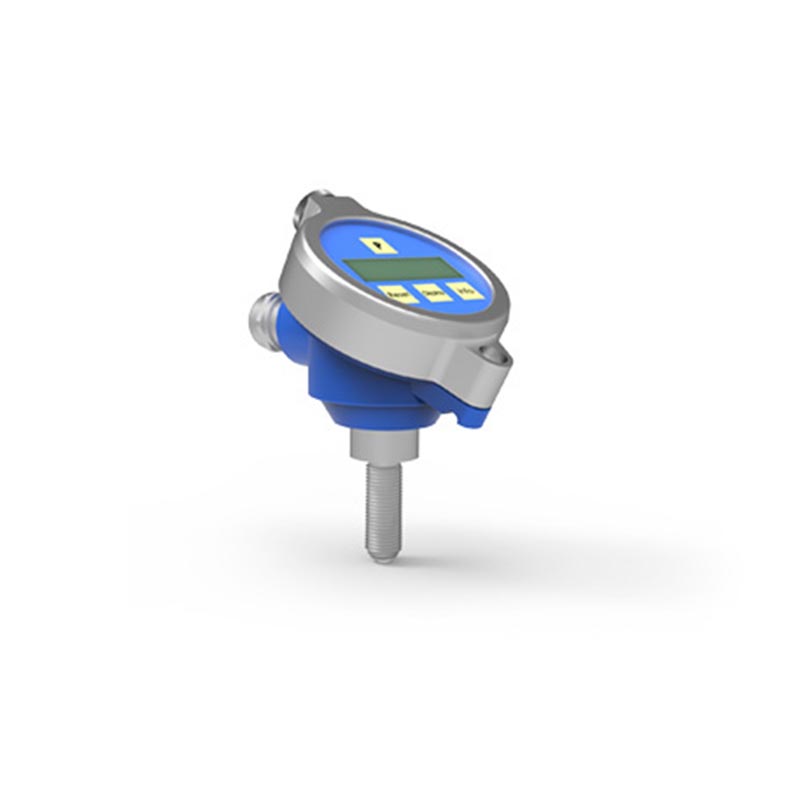

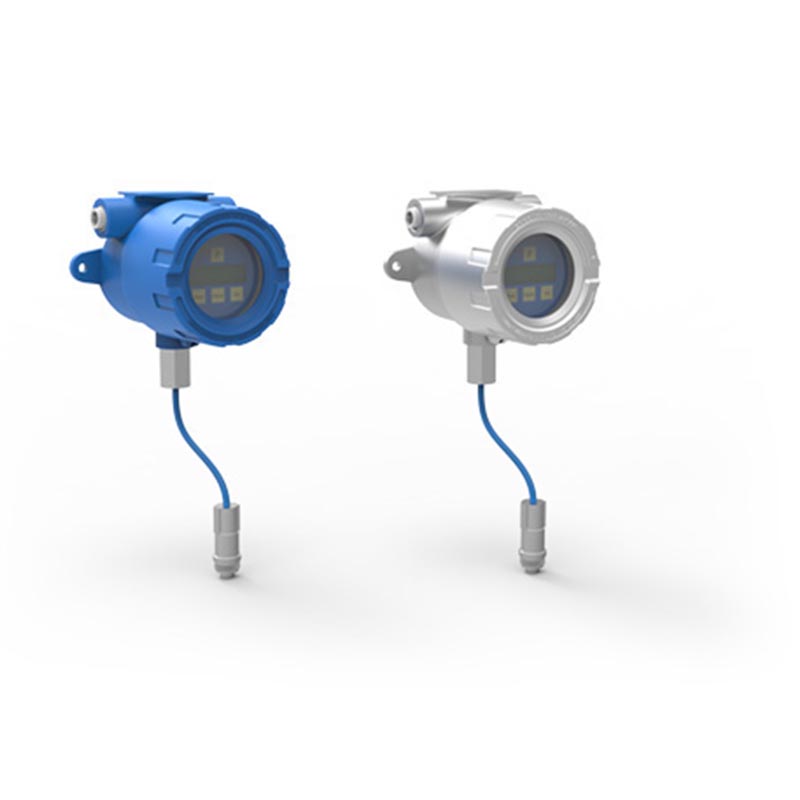

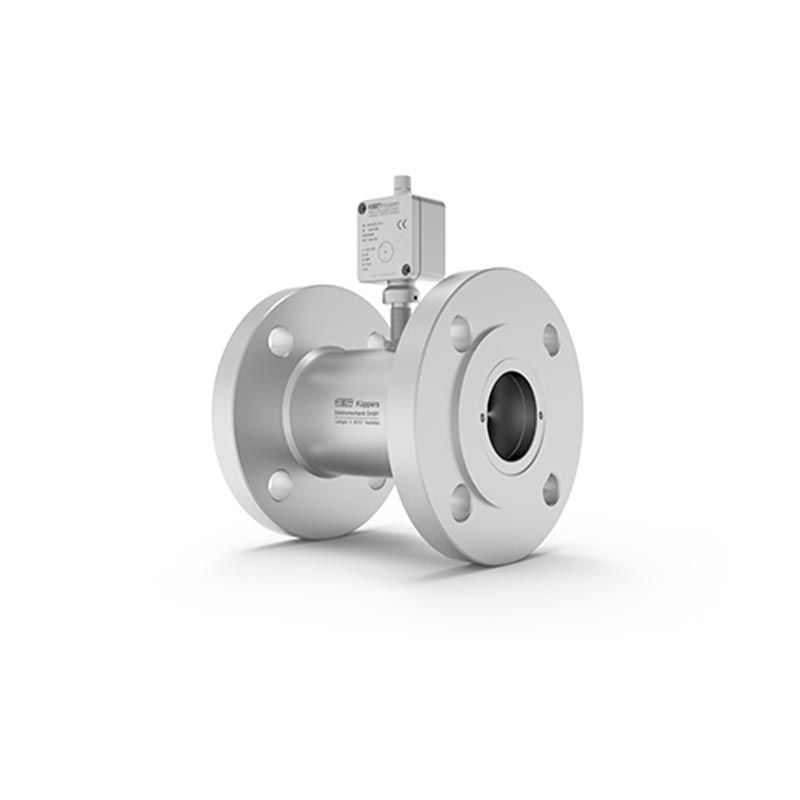

The VTC/VIC are high precision 4 – 20 mA pickups with a display and a frequency output.

All versions come with a graphic display, an intuitive user interface, a scalable 4 – 20 mA output, a 20 point linearization and a digital output for flow, limit and batching. K-factor and display dimension are freely settable for adapting the unit to any meter and application.

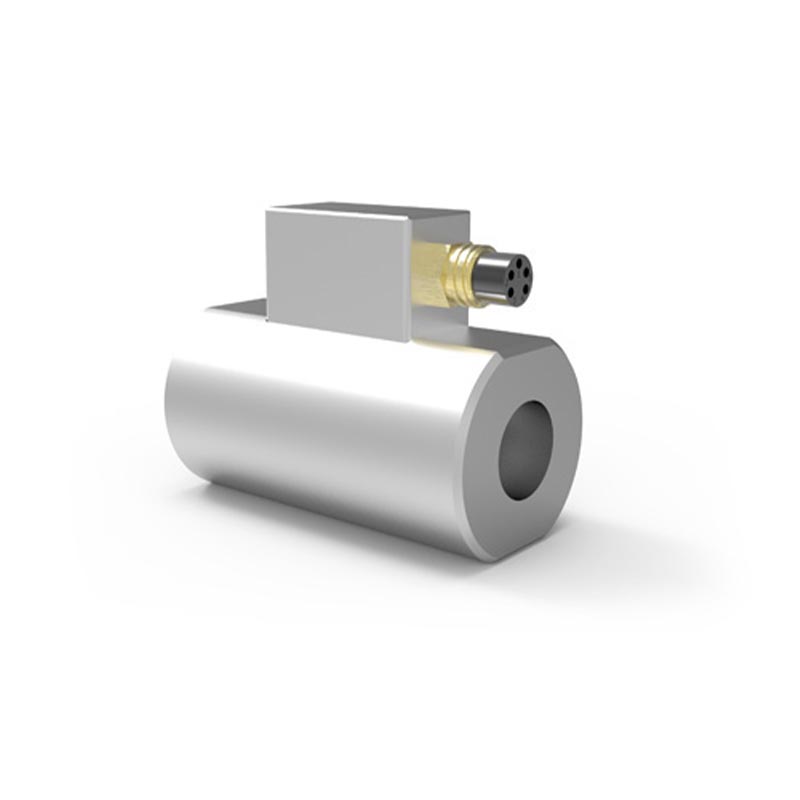

The VTC have a carrier frequency pickup, the VIC an inductive pickup. As an alternative to the proprietary KEM interface, a USB or HART interface is available.

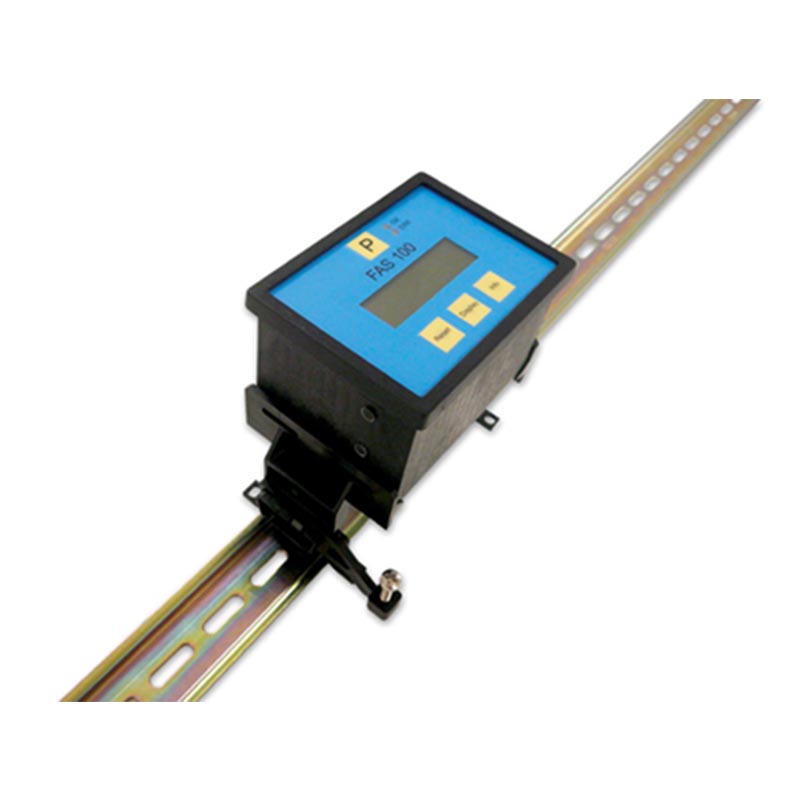

For fast test setups in the lab and easy setup of individual parameters, the PC based control SW EasyControl for WINDOWS is available free of charge.

Technical Data

- Carrier frequency or inductive pickup

- Analog Output: 4 – 20 mA passive (2 wire)

- Frequency output, freely scalable, Push Pull or NAMUR

- 20 point linearization of the measured value, 3 banks

- Control input

- KEM interface (standard) or USB or HART

- Ex Protection: ATEX Ex II 2G Ex ia IIC T4 Gb

Features

- High accuracy

- Intuitive user interface

- Remote control SW free of charge

Accessories

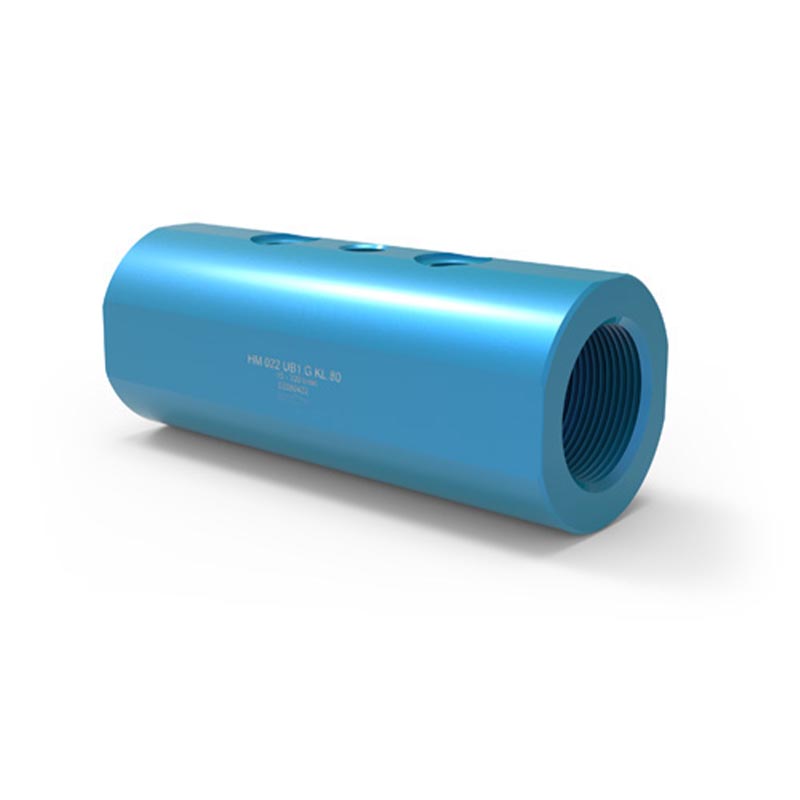

- Interface Converter for devices with KEM interface (CON.USB.WT)

- 24 V Wall Plugin Power Supply (SN1-24)