for lubricating and non-lubricating media

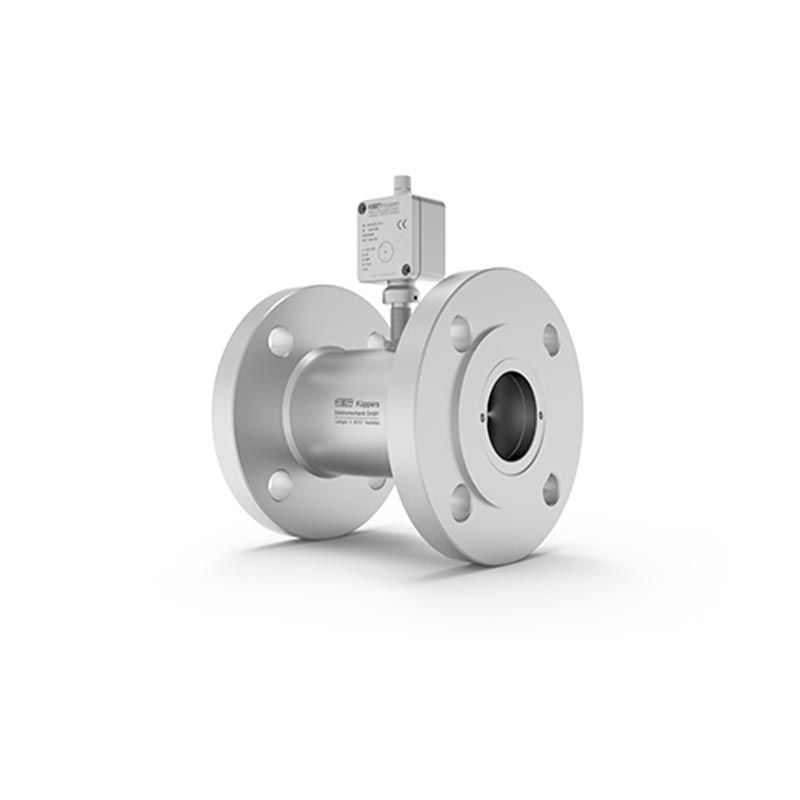

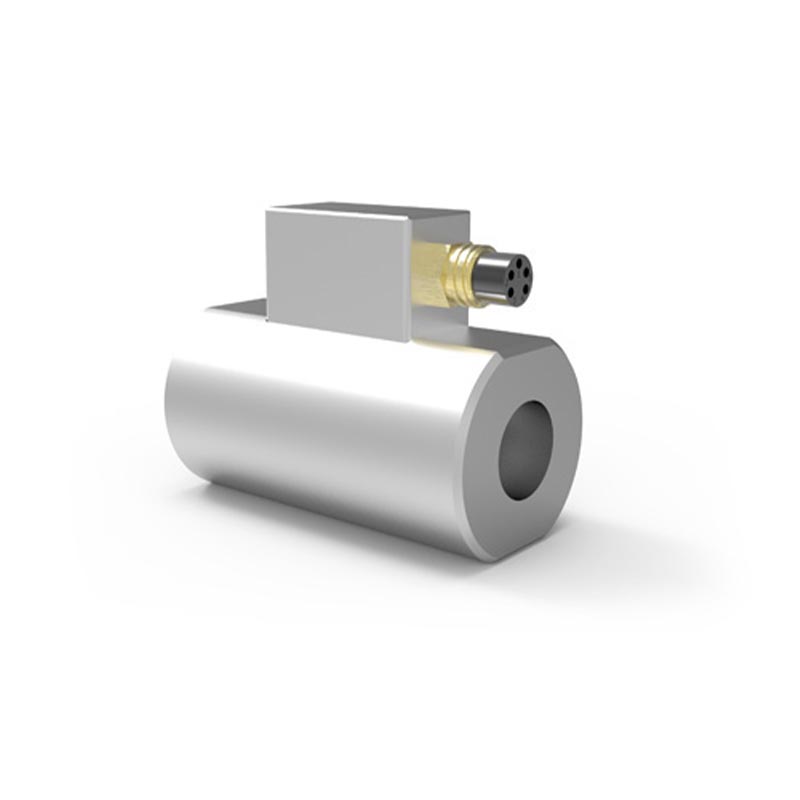

The HM F turbine flow meter series (F for flange connections) is used to measure continuous and discontinuous flow rates. They are mainly used for lubrication and non-lubrication media. They are particularly suitable for low and medium viscosity liquids, such as water, emulsions, glycol mixtures and light oils.

Only high-grade steels that even withstand corrosive liquids are used in the production of turbine flow meters. There are no welding seams in contact with the media thanks to the innovative design. Combined with the use of tungsten carbide bearings, the HM F guarantees optimum measurement accuracy and an extremely long service life even under the toughest application conditions.

Technical Data

- Measuring Ranges: 1 bis 10,000 l/min

- Measuring Accuracy: up to ±0.5 %

- Repeatability: ±0.05 % (in standard measuring range & under the same conditions)

- Linearity: ±1 % of actual flow

- Measuring Span:

- Standard: 1:10

- Extended: on request

- Viscosity Range: 1 up to 10 mm²/s

- Materials:

- Housing and internal parts: DIN 1.4404 [AISI 316L]

- Wheels: DIN 1.4462 [AISI S31803]

- Bearing: Tungsten carbide sleeve bearing

- Pressure: 16 up to 250 bar [232 up to 3,626 psi]

- Medium Temperature: -60 °C up to +350 °C [-76 °F up to +662 °F]