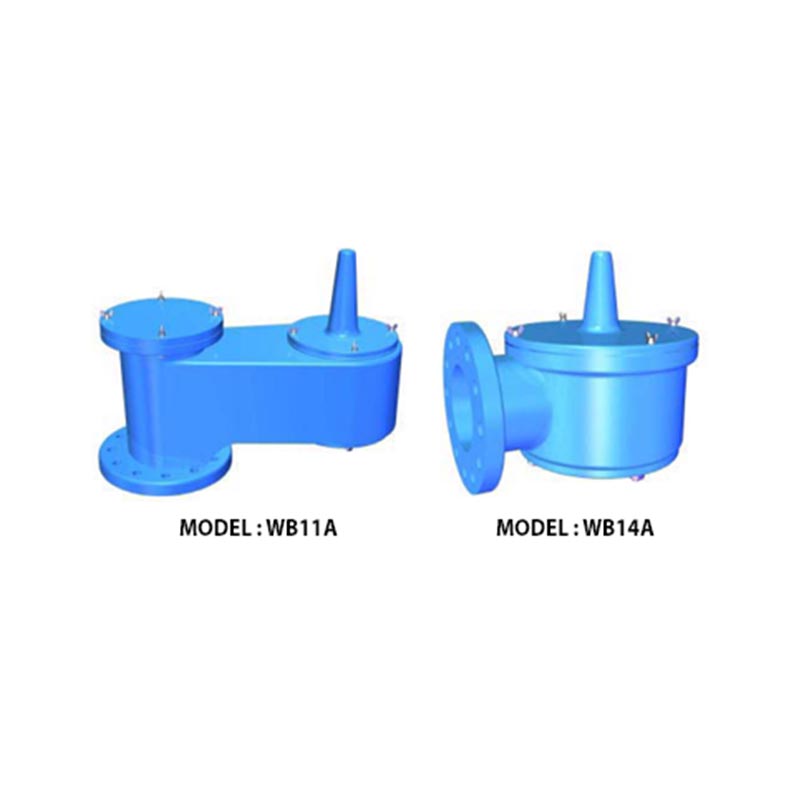

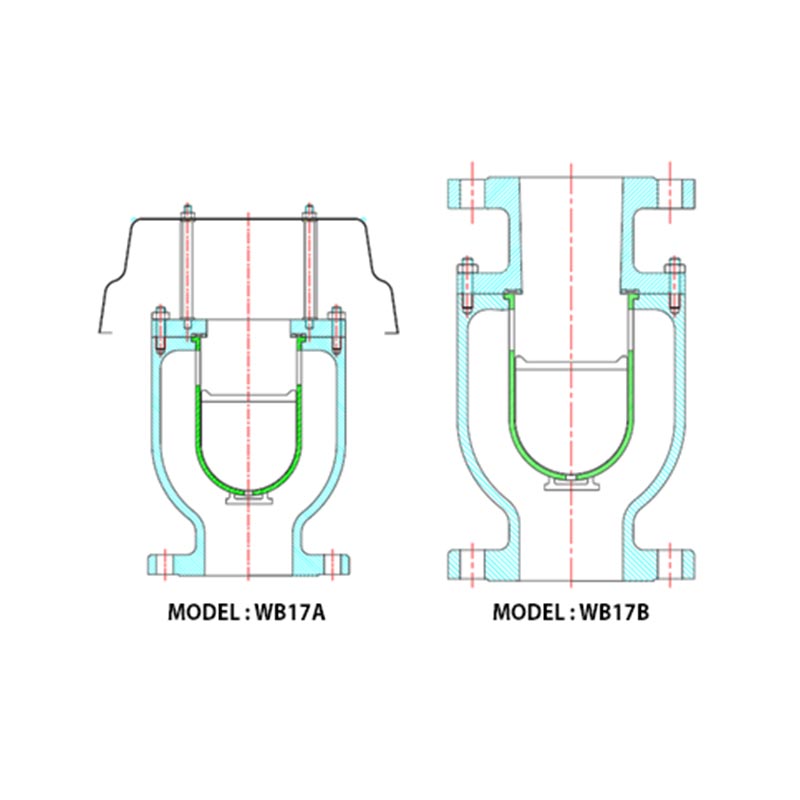

· Model WC511 float check valve is side-mounted type to install in water sump of floating roof deck and Model WC512 is bottom mounted type to install under water sump of floating roof deck.

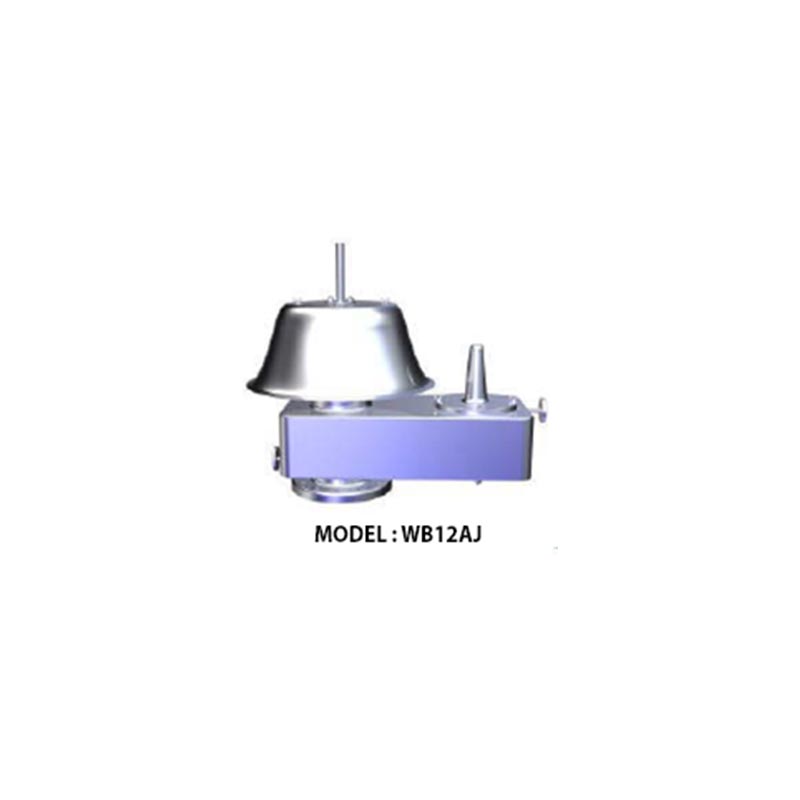

- Side Mounting Type, Bottom Mounting Type

- Size : 3” through 8”

- Available in : Carbon Steel, Stainless Steel.

- Other size and material to be consulted by factory.