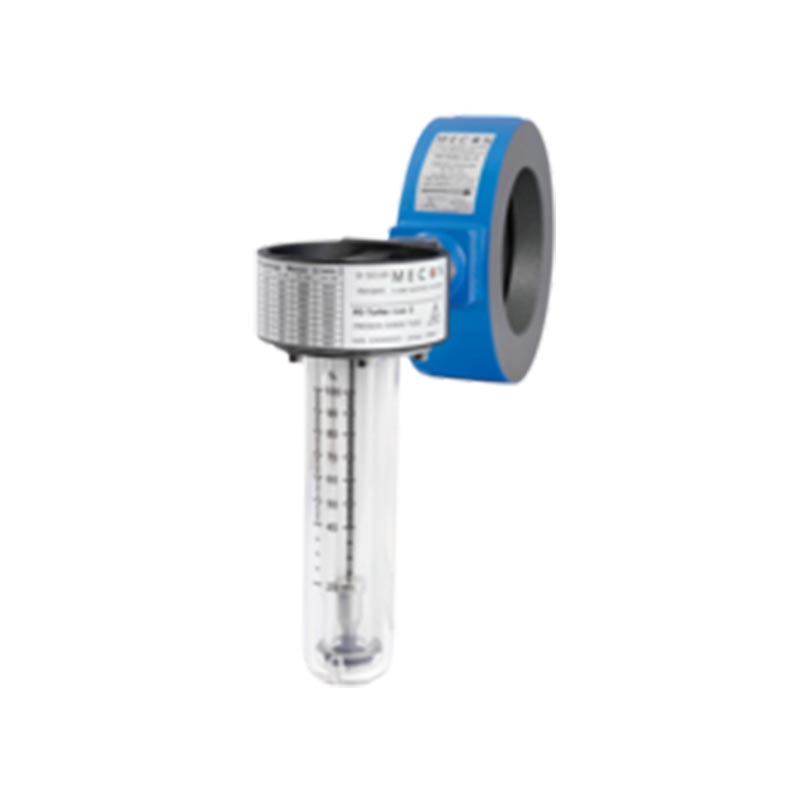

The mag-flux HTL hydrant tester is used in fire protection as well as in water management and serves for quick and easy performance testing of hydrants – among others according to W 405 and DIN 14462. The mobile flow and pressure measuring device is extremely robust. As it has no moving parts, it causes no pressure loss and is easy to clean with its splash-proof housing and can also be used in rainy weather without any problems.

Flow, pressure and new temperature measurement¹ of the hydrant

Equipped with the latest software, water pressure, flow rate and total flow rate are displayed from the beginning of each measurement. The device measures creeping quantities and carries out measurements of fire water or well water quantities. Now the temperature can be measured and documented optionally.

For the water industry, it is possible to determine the FNU values by means of separate turbidity measurement, especially during flushing campaigns, and thus to adapt the flushing strategy efficiently and in a resource-saving manner.

Data transfer via Bluetooth from the hydrant tester to the mobile device via app

The measuring process can now be controlled not only by the easily readable display but also by the practice-proven app from wasserkarte.info. All measured data for pressure, flow, temperature and turbidity are transmitted live from the hydrant tester to the app. The measuring protocols as well as diagrams are displayed directly as preview. The holistic solution for hydrant maintenance from documentation, planning, localization, performance to maintenance. http://wasserkarte.info/hydrantenwartung/leistungsmessung/